I feel pretty secure in my boat. I stay warm and dry with my spray deck in place. Waves can roll over the boat without my being concerned with swamping. I can stay dry in a sudden cloudburst too. But a significant leak from some unknown source made me suddenly feel vulnerable, and somewhat out of control.

On the 2007 Great Hudson River Paddle I would suddenly feel cold water on the undersides of my thighs. Sometimes it would creep up over the lip of the seat and leave me sitting in a cold puddle. I would pump and sponge the cockpit dry at each stop on the worst days. It seemed that every time I looked there was a quart or two of water sloshing around the inside my previously dry boat. I noticed that the problem was worse on days when there was some wind and wave action to contend with, but there was usually some water every day. Was my spray deck leaking? Was there a problem with the hull? Did I have a loose deck fitting? I just didn’t know. So I bailed and sponged the boat at every stop along the way from Albany to Manhattan.

When I returned home, I set about finding the leak. I checked all the deck fittings and tightened any that seemed the least bit loose. I gave the boat a good visual inspection inside and out, but found nothing obvious. Then I carried the boat out onto the lawn and began filling the cockpit with water. If water can leak in, it can also leak out. I watched as the water crept higher in the cockpit, but could detect no leak. Finally, with the water reaching the cockpit coaming, a stream began pouring from the skeg controller – the sliding mechanism that raises and lowers the skeg.

Now I knew how the water was getting out, but just where was it getting in? In order to see the glassed in area that covered the controller and the control wire to the skeg on the inside of the boat, I first needed to remove the thin foam pad covering the thigh brace. The foam was not tightly glued in place and I was able to peel it back with a little effort and a utility knife. I needed a way to find exactly where water was getting in.

I have Talic Seahorse boat stands that are great for working on a kayak. I set the boat on the stand and rolled it on its side, so that the hollow around the skeg controller would hold water. I filled this slot with water, then watched the inside of the boat. Before long, there was water on the inside. It was wet where the controller was glassed into the boat, but the wet spot was disbursed over a wide area. I could not identify the exact location of the leak.

I needed a way to stain the water to highlight the location of the leak inside the boat. I thought food coloring might do the job. I got some green food color from Lisa’s baking supplies and mixed a drop or two with the water I poured into the skeg controller slot. Then I waited. Within a few minutes a dark green stain appeared along the front edge of the fiberglass cloth that held the controller in place. Apparently the cloth had not sealed the space around the controller mechanism and wire completely. I had found my leak!

The next question was how would I affect a repair? I decided to go to my local West Marine store for advice. After some conversation and a review of several products, I decided on a fiberglass repair kit that contained fiberglass tape and a two-part resin, along with the tools I needed to apply the materials. It cost me all of $14.95 plus tax!

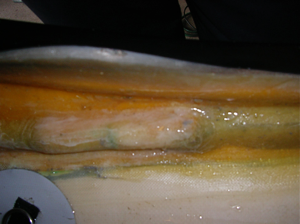

Back in my garage, I set the boat on its side again and held it in place with straps. With a light placed in the cockpit, I could work on the repair area without standing on my head. I The underside of the repaired skeg controler, inside the cockpit

I have since found that skeg leaks, either around the controller or the skeg box in the stern of the boat, are common. Ten months later on the Potomac River, my cockpit wasI first tried duct tape alone. This stopped the leak but didn’t let me operate the skeg control. Then I taped a light weight plastic bag over it, which gave me some use of the controler.

Using the same process as before, I found that the leak had moved from in front of the controller to behind it. I repaired this leak in the same way, but then found that the leak, now reduced to a few drops, had moved from the cockpit to my day hatch. It was following the path of the glassed in controller wire.

It was difficult making a repair inside the day hatch. I had to put a light in the cockpit so that it would shine through the translucent bulkhead, into the hatch area. To see my work, I taped a mirror in the hatch and worked in reverse, viewing all my efforts in the mirror, when not simply operating by touch. Using a combination of resin and tape, followed by a generous dose of silicone calk, I seem to have finally stopped all of the leaking (for now). It’s nice to be paddling warm and dry once again!

Some of you may have had similar problems withThe gap in the fiberglass tape where the leak occurred in the day hatch is clearly visible just below the hex nut in this picture.